The dairy sector in the country has been growing at a significant rate over the years. In the 1950s, the nation grappled with an acute scarcity of milk, but over the decades it has transformed into the world’s top milk producer. Today, dairy farming supports the livelihoods of nearly 80 million rural families.

The White Revolution of the 1970s marked a decisive shift, propelling India to the forefront of global milk production. According to industry data, India now produces about 198.4 million metric tonnes (MT) of milk annually, and output is expected to grow by around 5% year-on-year in the near future. By contrast, global milk production averages a modest 2% annual increase. For over two decades, India has led global milk production, delivering around a quarter of the total volume.

The availability of milk in India has also risen significantly to 471 grams per day in 2023–24, as against the global average of 322 grams. Over the last decade, Indians have seen a 48% rise in per capita milk availability, highlighting the sector’s rapid growth and importance.

Role of Digitalization in Milk Production

India’s dairy sector still remains unstructured. But the past few years the country has witnessed the growth of technology-led start-ups bringing digital solutions. Their focus is on improving farmer productivity, minimizing wastage, and simplifying the highly complex dairy supply chain, which is affected by factors like temperature sensitivity, lack of cold storage, and short shelf life.

Technologies such as IoT devices, GPS tracking, and advanced analytics are helping monitor milk quality, quantity, and logistics in real time. This integration provides the much-needed support to farmers while enhancing supply chain transparency and efficiency for industrial players.

1. Centralized Data

A digitized system guarantees that all parties use the same accurate and updated data. Traditionally, records in the dairy sector were maintained on paper or spreadsheets, or sometimes only in employees’ memory. A centralized digital system offers 24/7 access, reduces dependency on individual staff members, and minimizes errors while improving decision-making.

2. Business Continuity

When employees leave or are unavailable, their knowledge doesn’t disappear with them—thanks to digital records. Information can be used to train new hires quickly and maintain productivity. For instance, logistical details like the best routes to farms remain accessible to the entire team, ensuring uninterrupted operations.

3. Traceability

From farm to consumer, traceability is crucial in the food industry. With digital tools, issues can be identified and resolved quickly, whether they stem from raw material shortages or contamination risks. Features like First-Expired-First-Out (FEFO) tracking make it easier to manage inventory and maintain product safety.

4. Forward Planning

Dairy production is seasonal, and demand also fluctuates. Using forecasting tools and cost modeling, dairy companies can prepare for peak milk supply periods or festive consumer demand. This ensures better resource allocation, smoother cash flow, and cost efficiency.

5. Real-Time Visibility

Unexpected events—like contamination in milk batches—can be devastating if unnoticed. Real-time monitoring solutions help detect such issues early, preventing large-scale losses and maintaining product quality.

6. Sustainability & Emission Reduction

Modern logistics software allows companies to measure and track greenhouse gas (GHG) emissions. By analyzing transport routes and vehicle performance, businesses can find ways to cut down emissions, aligning with both consumer expectations and environmental responsibilities.

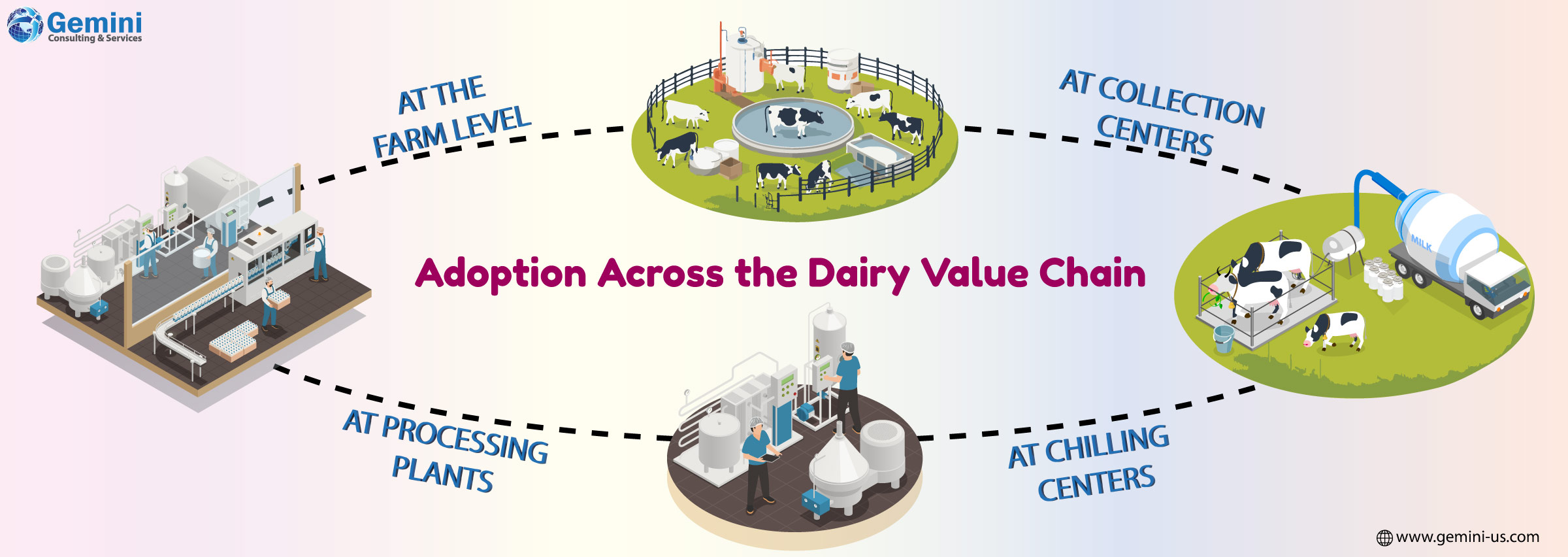

- At the farm level: Farmers and their cattle are registered on digital platforms, often through mobile apps, with unique IDs. Field agents assist farmers who may not be tech-savvy, helping them record production data and track income and expenses through digital passbooks.

- At collection centers: IoT-enabled automatic milk collection units ensure transparent procurement and accurate quality-based pricing. This reduces pilferage and strengthens farmer trust.

- At chilling centers: IoT-based sensors track temperature, milk quality, and energy usage in real time, while GPS systems enable monitoring of tanker routes before the milk is delivered to processing units.

- At processing plants: Every stage of production is digitally recorded for quality assurance, ensuring consistency and transparency across the supply chain.

Challenges in Digital Integration

Despite significant progress, the industry still struggles with fragmented data management. While digital tools capture vast amounts of information, much of it remains siloed at different nodes of the supply chain. A standardized framework is necessary to integrate these datasets, unlocking valuable insights for better forecasting, efficiency, and traceability.

The key lies in creating a cohesive digital ecosystem that allows information to flow seamlessly from farms to final products, ensuring end-to-end visibility.

With more than a decade of expertise in technology, Gemini Consulting & Services empowers dairy enterprises to digitally transform their supply chains. Contact us to discover how our digital solutions can enhance transparency and efficiency across your dairy operations.

Conclusion

India’s dairy industry finds itself balancing heritage with the adoption of new technologies. With the adoption of IoT, cloud platforms, blockchain, and data analytics, the industry has an opportunity to revolutionize supply chain management and enhance consumer trust. This can lead to significant increase in sales, monitoring temperatures of milk and water flow, and automated machinery operation through IoT.

Digitalization facilitates tracking the procurement and sales of vehicles, tankers, and puffs to improve on-time deliveries for customers using GPS. Real-time data synchronization will facilitate the organization's growth toward its defined vision and mission, ensuring satisfaction for shareholders, customers, and suppliers while promoting high sustainability.

Digitalization promises not only better productivity, transparency, and sustainability but also stronger food safety and quality assurance. As India continues to lead the world in milk production, embracing these innovations will be essential to remain competitive and meet the evolving demands of consumers in a dynamic global marketplace.